Meat Product Dryer-Beef and Pork Drying Process

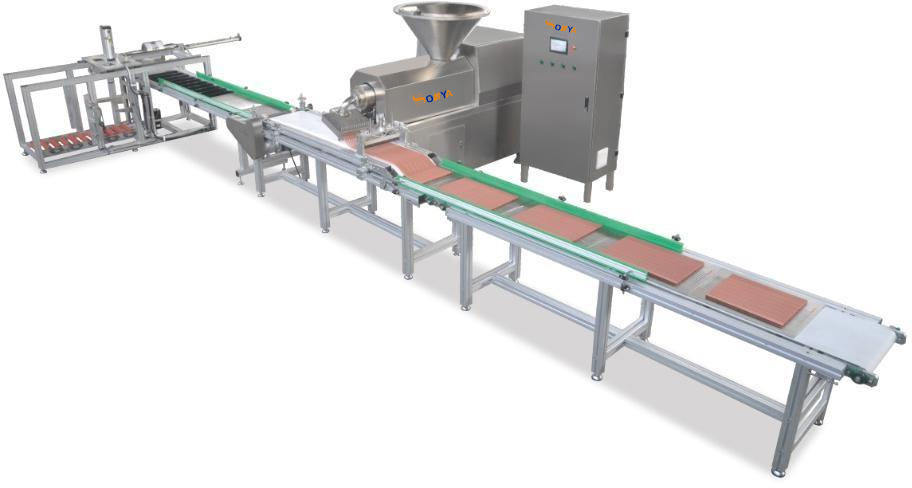

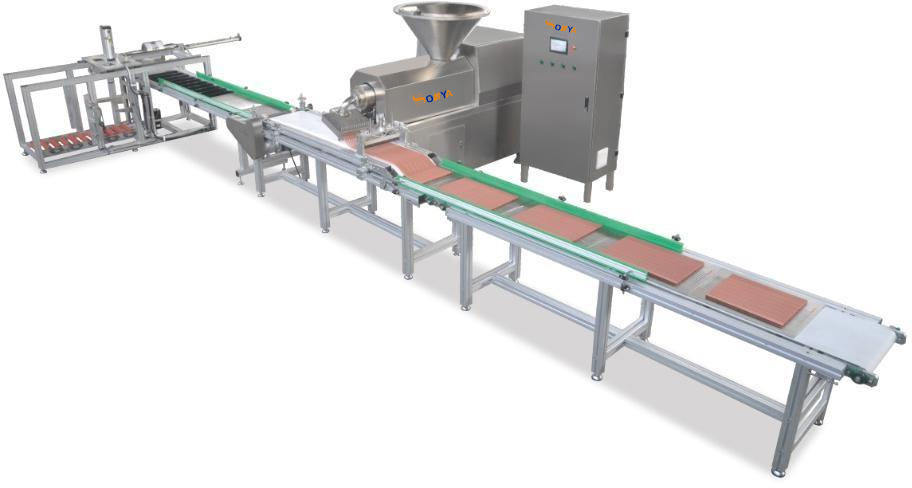

Prospects for the future development of puffed food

08/15/2022

The Puffed Products Enter The "Fast Lane"

08/24/2022

Meat Product Dryer-Beef and Pork Drying Process

meat products beef jerky Sonya machine

The main structure of the meat product drying room is divided into: heat pump drying dehumidifier, drying room, hot air circulation system, dehumidification system, automatic intelligent control system, and high-efficiency waste heat recovery dehumidification device.

Meat products Sonya machine dryer

There are several difficulties in drying meat products. During the drying process, it is easy to cause the material to become sour and deteriorate. Therefore, it is necessary to accurately and effectively control the drying humidity of the drying room, and pay attention to the circulating air flow.

Steps of drying beef in food dryer

Generally speaking, Sonya machine jerky has many flavor options, such as spiced, spicy, pepper, etc., but the processing technology is similar, the main steps are material selection → cooking → slicing → cooling → drying → packaging and several other processes .

1. Raw material selection

Fresh meat with firm, lean meat is preferred. If it is frozen meat quality, it needs to be defrosted in the defrosting room. After the beef is thawed, it can be used until the color and quality return to normal.

2. Cutting

Cut the selected buttocks and hind legs into the required shapes (sheets, strips), when the output is large, you can choose the cutting equipment to complete, the cut beef is more uniform, and it is easy to hang the material when drying.

3. Drying

The drying process generally goes through three stages: preheating, constant temperature, and quick drying. After drying, the moisture content of the beef is about 15%, which is suitable for long-term storage. Generally, in an indoor environment with a temperature of 40°C and a temperature of about 60%, a batch of beef can be dried in about 36 hours. At this time, you can see that the color of the beef is dark red, and the hand feels dry and hard.

The peak season of food processing is coming, and all food factories are busy. Jerky food is a favorite snack among consumers.

meat products beef jerky Sonya machine

The main structure of the meat product drying room is divided into: heat pump drying dehumidifier, drying room, hot air circulation system, dehumidification system, automatic intelligent control system, and high-efficiency waste heat recovery dehumidification device.

Meat products Sonya machine dryer

There are several difficulties in drying meat products. During the drying process, it is easy to cause the material to become sour and deteriorate. Therefore, it is necessary to accurately and effectively control the drying humidity of the drying room, and pay attention to the circulating air flow.

Steps of drying beef in food dryer

Generally speaking, Sonya machine jerky has many flavor options, such as spiced, spicy, pepper, etc., but the processing technology is similar, the main steps are material selection → cooking → slicing → cooling → drying → packaging and several other processes .

1. Raw material selection

Fresh meat with firm, lean meat is preferred. If it is frozen meat quality, it needs to be defrosted in the defrosting room. After the beef is thawed, it can be used until the color and quality return to normal.

2. Cutting

Cut the selected buttocks and hind legs into the required shapes (sheets, strips), when the output is large, you can choose the cutting equipment to complete, the cut beef is more uniform, and it is easy to hang the material when drying.

3. Drying

After hanging the meat strips in the drying room, start the air energy heat pump dryer and set the parameters. Note: The meat strips should not drip, hang up straight, do not stick to each other, and keep a little distance between the meat strips to facilitate ventilation and dry evenly.

The drying process generally goes through three stages: preheating, constant temperature, and quick drying. After drying, the moisture content of the beef is about 15%, which is suitable for long-term storage. Generally, in an indoor environment with a temperature of 40°C and a temperature of about 60%, a batch of beef can be dried in about 36 hours. At this time, you can see that the color of the beef is dark red, and the hand feels dry and hard.