Dog Treats Extruding Machine

Fish feed Production Line

03/31/2022

Meat Strips Processing Line

03/31/2022Dog Treats Extruding Machine

Different shapes of dog treats are produced by single-screw extruder. It can not only provide nutrition for dogs, such as protein, fat, vitamins, etc., but also meet dog’s habit of chewing. On the other hand, it can also works to strengthen teeth, clean mouth, remove tartar and reduce disease infection for dogs. Regular chewing would slow down the formation of dental plaque, tartar and gingivitis. The products can be in many shapes, like twist, bi-color, core-filling,etc..

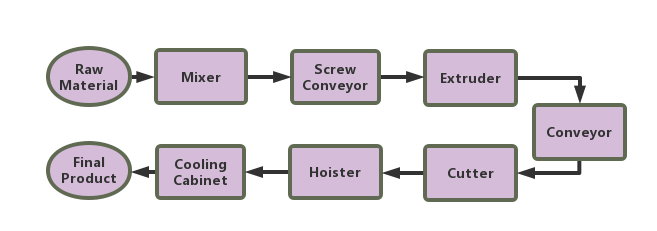

Production Flow Chart:

Mixer: Mix raw materials, water and other materials.

Screw Conveyor: It is used to lift the mixed materials into the single-screw extruder hopper.

Extruder: The raw materials are evenly fed and extruded by the screws.

Conveyor: Used to convey semi-finished product to the cutting machine.

Cuutter: Used to cut the chewing into pieces of the same size.

Hoister: Used to lift food into the cooling cabinet.

Cooling Cabinet: It is used to cool the semi-finished pet treats to the final product..

Parameters:

Model | Installed Power | Power Consumption | Capacity | Dimension(mm) |

SY-100 | 40kW | 30kW | 100-160kg/h | 17000x2000x2050 |

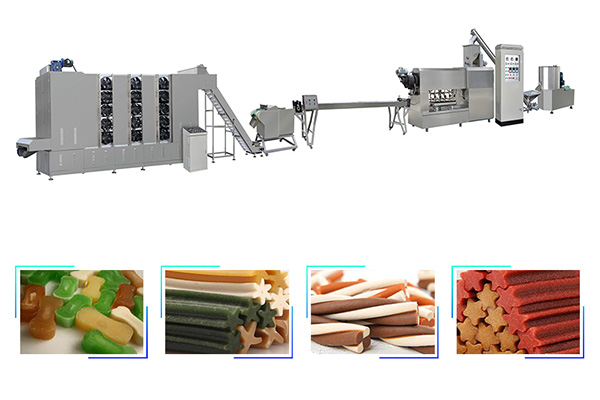

Machine Details:

Product Sample: