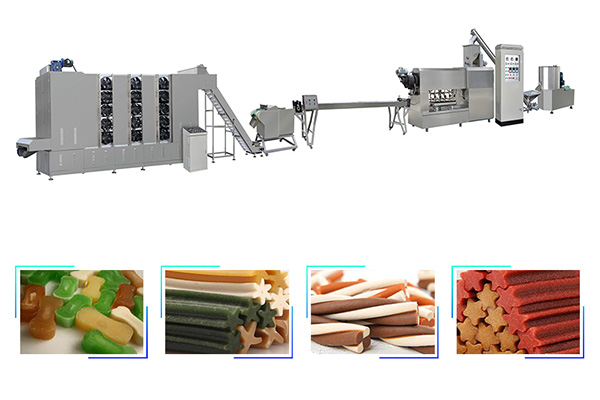

Meat Strips Processing Line

Dog Treats Extruding Machine

03/31/2022

Meat Strips Processing Line

03/31/2022Meat Strips Processing Line

Meat strips take meat as the main raw material and then add a certain amount of protein powder and other nutrients. Meat strips are produced by extrusion and cutting. Our meat strips production line is simple to operate. And the size of meat strips can be adjusted conveniently.

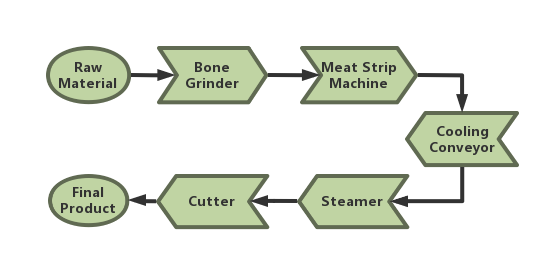

Production Flow:

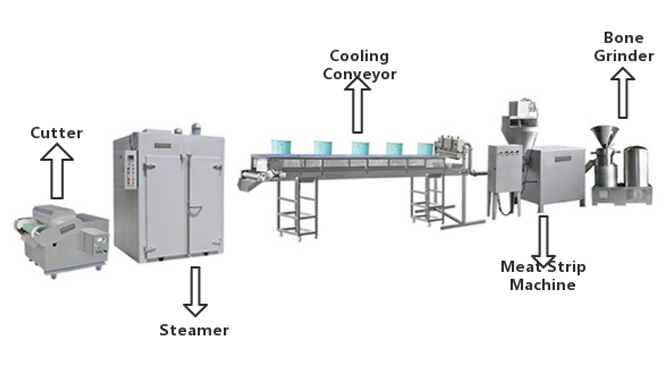

Bone Grinder: Used to grind bones, fresh meat, animal organs and other materials into meat mud.

Meat Strip Machine: Used to extrude the meat mixture into strips. Various sizes would be produced as per clients’ demands.

Cooling Conveyor: Used to cooling the products.

Steamer: Used to bake meat strips whose temperature and baking time are full automatic and adjustable.

Cutter: Used to cut the meat strips.

Parameters:

Model | Power(kw) | Capacity(kg/h) | Dimension(mm) | Weight(kg) |

SY160 | 18 | 200-300 | 8630x3570x685 | 3000 |

Machine Details:

Product Sample:

Advantages:

Productivity: The continuous and automatic processing guarantee it’s high productivity. It’s easy to operate and maintain.

Smart Control System: PLC control ensures optimized processing parameters for each recipe.

Complete production line is with reasonable design and smart control system to ensure high quality production and to reduce labor cost.