Rice Cracker Production Line

Fortified Rice Making Plant

02/08/2022

Nutrition Powder/Baby Rice Powder Production Line

04/06/2022Rice Cracker Production Line

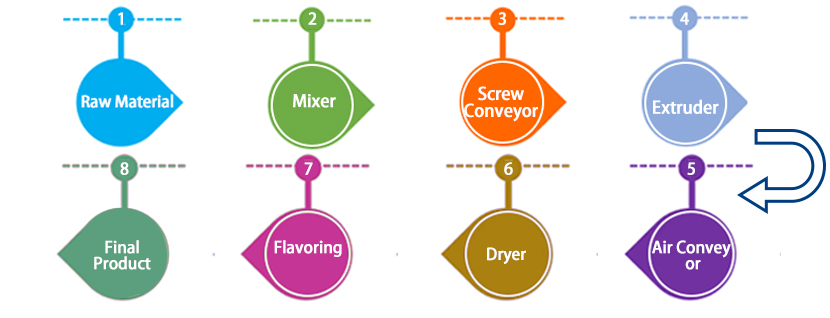

Features:

1. Rice cracker production line takes corn, rice, wheat, oat and other grains as materials to produce extruded puffed snacks with crispy taste and full shape.

2. The production is designed according to clients’ demands to extrude different shapes, like round, triangle, square, stars, flower, heart, etc.

3. It’s flexible production and can also work with core filling machine to produce jammed rice cracker.

4. It can work fully automatically from mixer, feeding, extruding, conveying, drying, flavoring and packaging. Multi-head vertical packaging machine is also optional for you.

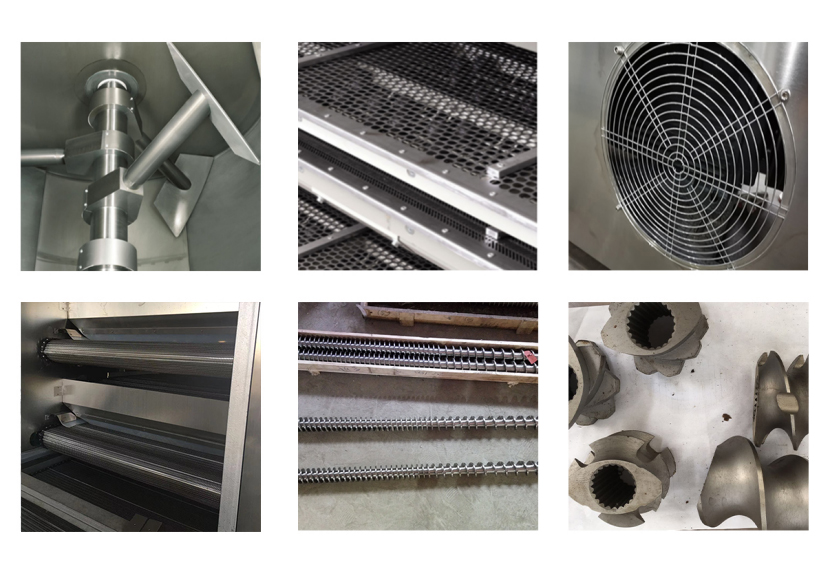

5. The screws are made by alloy steel and special craft with long lifetime. The forced lubrication system also extends the running time of equipment transmission.

This processing line from feeding, extruding, shaping ,cutting , oil spraying to finished products are done once time automatically. Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully. The forced lubrication system, by guaranteed equipment transmission longer life。

Core Filling Snacks Extruding Line can produce all kinds of extrusion products, such as snacks, core filling food, nutritional powder, breakfast cereal, baby food, etc.

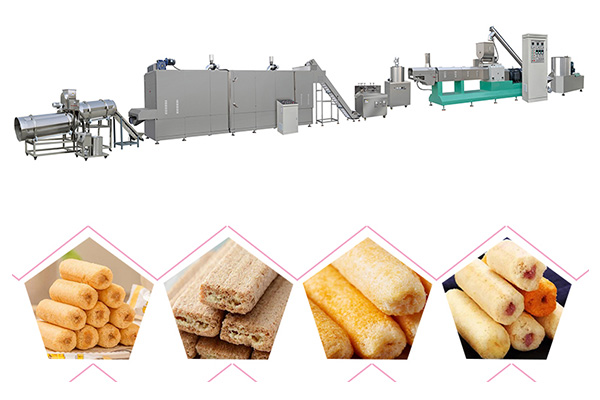

Technical Parameter

Model | SY-65II | SY-70II | SY-85II |

Capacity | 100-150kg/hr | 150-260kg/hr | 250-350kg/hr |

Power | 92kw | 110kw | 120kw |

Dimension | 22 x 5 x 3m | 25 x 5 x 3m | 30 x 5 x 3m |

Workers Needed | 2-3 | 2-3 | 3-4 |

Machine Display

Samples: