Oatmeal Chocolate Machine

Granola Bar Cutting Machine

02/14/2022

Puff Snack Production Line

04/06/2022Oatmeal Chocolate Machine

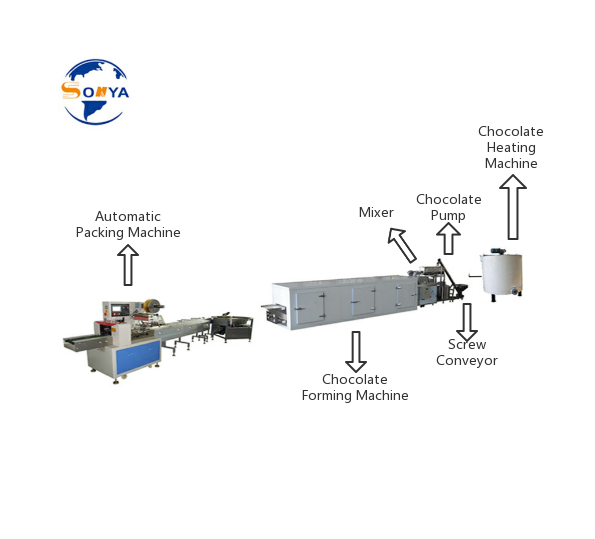

The oatmeal chocolate machine is mainly applied in the production of oatmeal chocolate, purple potato chocolate and cereal chocolate,etc.. The oatmeal chocolate machine is with advantages of automatic leveling, automatic cooling and automatic de-molding. It is of characteristics of large capacity, high efficiency and labor saving while one worker can handle it. It can produce various shapes and patterns through different moulds, like round balls, square bars, semicircular, semi cylindrical, etc..

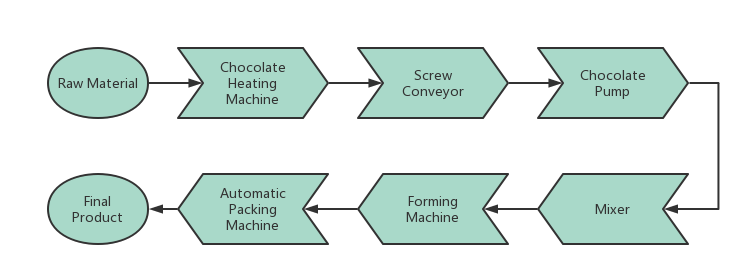

Production Flow:

Chocolate Heating Machine: It’s used for melting, stirring and heat preservation of chocolate.

Screw Conveyor: It’s used to convey the materials to the feeding hopper of chocolate pump.

Chocolate Pump: It’s used to transport the chocolate liquid to the mixer.

Mixer: It’s used to mix oatmeal and chocolate evenly and automatically.

Oatmeal Chocolate Forming Machine: It’s used for automatic molding of chocolate.

Automatic Packing Machine: It’s used to wrap and pack the products as individuals.

Parameters:

Model | SYA-100 Oatmeal Chocolate Machine |

Output(kg/24hours) | 8000-10000 |

Speed of Cooling(T/min) | 4-5times |

Shape of Goods | Customization |

Voltage(V) | 380 |

Main motor power(kw) | 5.5kW |

Operating Temperature(℃) | 30-35 |

Size of Machine (mm) | 7200*2350*1950mm |

Cooling Capacity(kw) | 17kW |

Details:

Product Sample:

Advantages of Sonya Oatmeal Chocolate Machine:

1. The chocolate transfer and mixing temperature are controlled and stabilized by the constant temperature control device.

2. It is equipped with automatic alarm system which will alarm when the material level is low.

3. It achieves automatic feeding, automatic leveling, automatic cooling and automatic demoulding.

4. It is of large output, high efficiency and labor saving.

5. The molds are quick and easy to change.

6. The forming unit is of multi- layers, which can save space for clients.

7. Different shapes are available as per your requirements.

8. Complete production line is with reasonable design and control system to ensure high quality products production.