Corn Flake Production Line

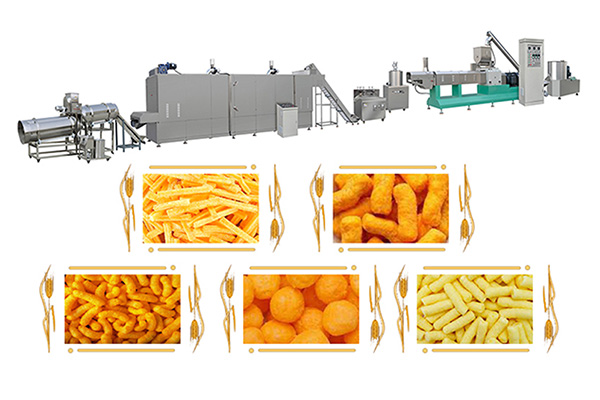

Puff Snack Production Line

04/06/2022

Fortified Rice Making Plant

02/08/2022Corn Flake Production Line

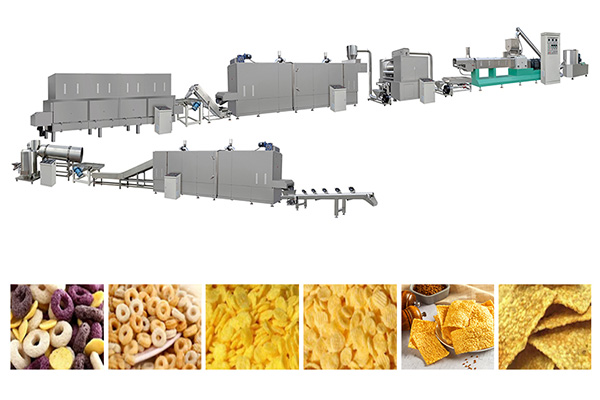

This machine can produce healthy non-fried instant cereal breakfast rich in vitamins and minerals. Simply mix it with milk, you can have a perfect breakfast. You can also put it in yogurt, ice cream or salad. Breakfast cereals are made of multiple materials such as corn, wheat and oats, which are well cooked and formed by twin-screw extruder. The products are crispy and have high nutritional value, which is suitable for people of all ages.

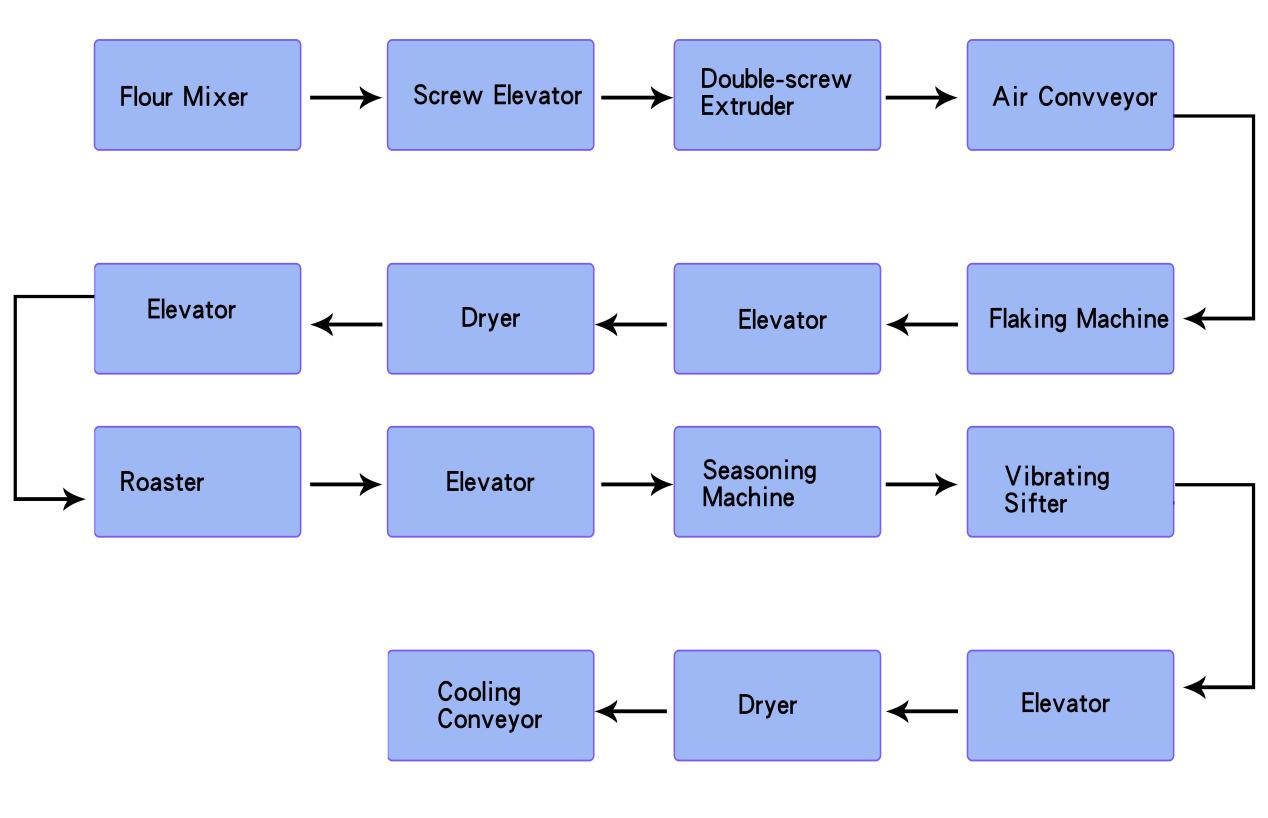

Production Flow:

Flour Mixer → Screw Elevator → Double-screw Extruder → Air Convveyor → Flaking Machine → Elevator → Dryer → Elevator → Roaster → Elevator →Seasoning Machine→ Vibrating Sifter → Elevator → Dryer → Cooling Conveyor

Parameters:

Model | SY-65II Corn flake production line | SY-70II Corn flake production line |

Installed power | 86kw | 119kw |

Power consumption | 56kw | 82kw |

Capacity | 100~160kg/h | 150~250kg/h |

Dimension | 34500x2000x2600mm | 35600x2000x2800mm |

Samples

Machine Display:

Advantages of Sonya corn flakes production line:

Productivity: The continuous and automatic processing guarantee it’s high productivity. It’s easy to operate and maintain. Flexibility: It can be applied in the production of breakfast cereals, buckwheat as well as corn flakes. Smart Control System: PLC control ensures optimized processing parameters for each recipe. Complete production line is with reasonable design and smart control system to ensure high quality production and to reduce labor cost.