Puff Snack Production Line

Oatmeal Chocolate Machine

04/06/2022

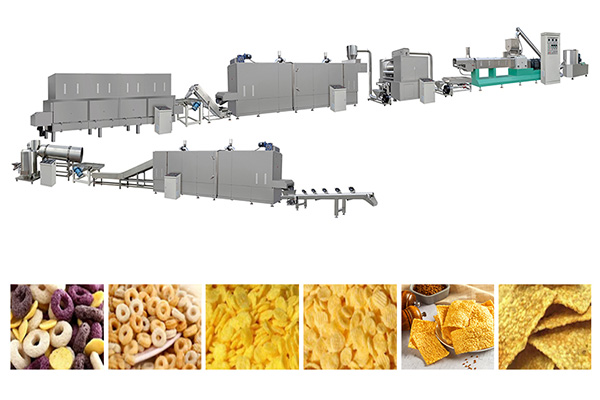

Corn Flake Production Line

04/06/2022Puff Snack Production Line

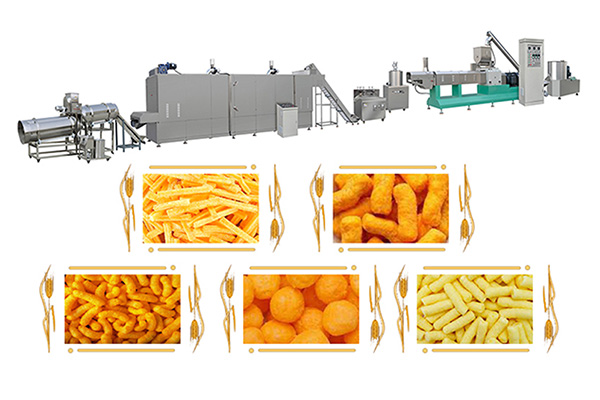

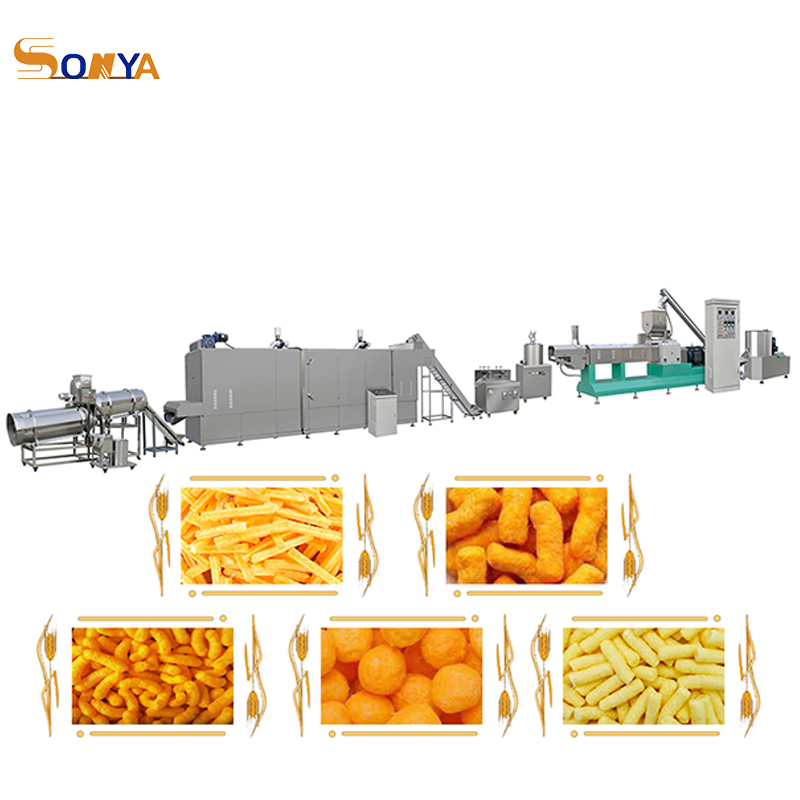

The puff snack extruding line has a high degree of automation from raw material preparation, extrusion, conveying, drying, flavoring to final products. The production line has the characteristics of flexible capacity and wide range of raw materials and final products. It’s automatic and easy to operate controlled by PLC. Various shapes of puffed snacks can be produced by changing different moulds which can customized as per clients’ requirements.

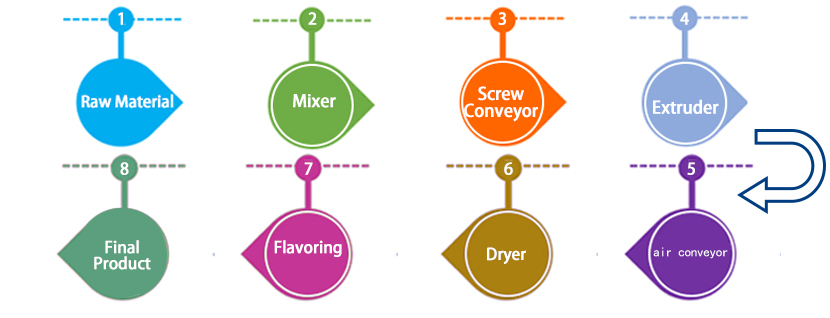

Production Flow Chart:

This corn puffs snacks processing line consists of mixer, screw elevator, twin screw extruder, dryer, elevator, flavoring machine, oil sprayer and packing machine.

This corn puffs snacks processing line consists of mixer, screw elevator, twin screw extruder, dryer, elevator, flavoring machine, oil sprayer and packing machine.

By changing the moulds of twin screw Extruder, many different shapes of corn puffed snacks will be produced. We can also customize.

Parameters:

Model | Installation Power | Actual Power | Capacity |

SY-65II | 81kW | 53kW | 100-150kg/h |

SY-70II | 115kW | 76kW | 120-240kg/h |

Advantages:

Productivity: The continuous and automatic processing guarantee it’s high productivity. It’s easy to operate and maintain.

Smart Control System: PLC control ensures optimized processing parameters for each recipe.

Complete production line is with reasonable design and smart control system to ensure high quality puff snack production and to reduce labor cost.

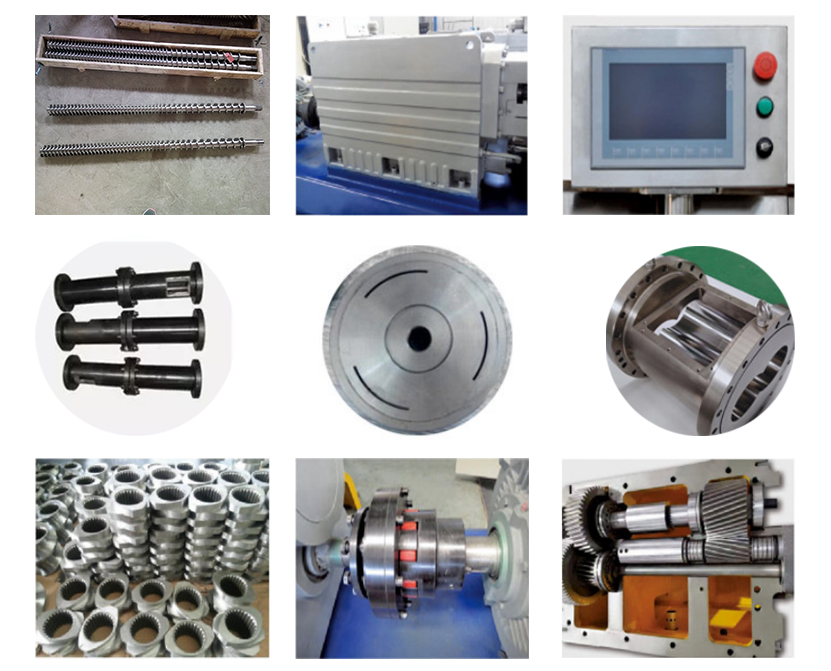

Machine Details:

Product Sample: