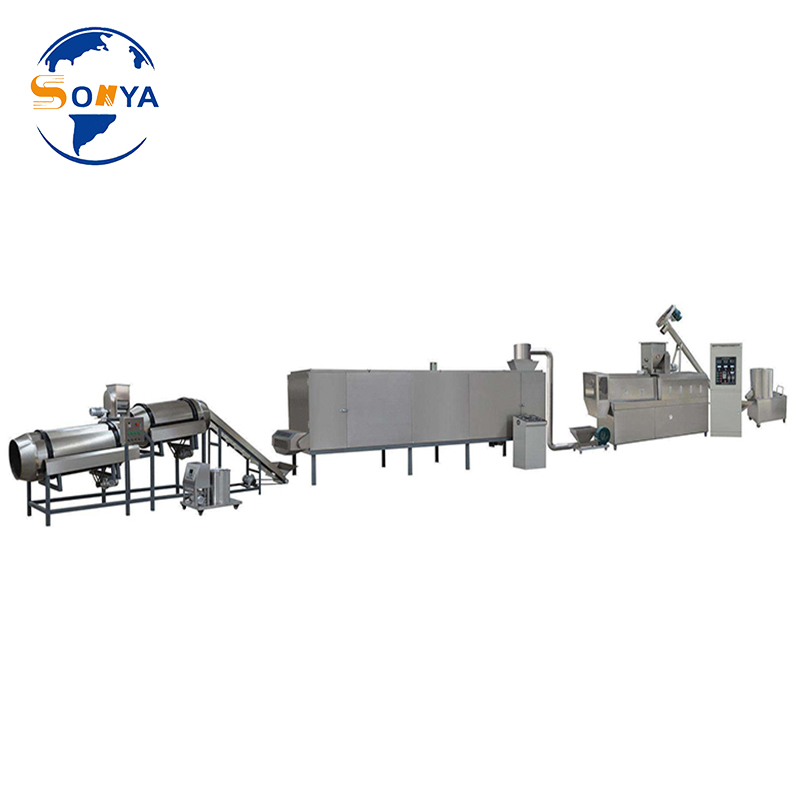

Macaroni Pasta Extruding Line

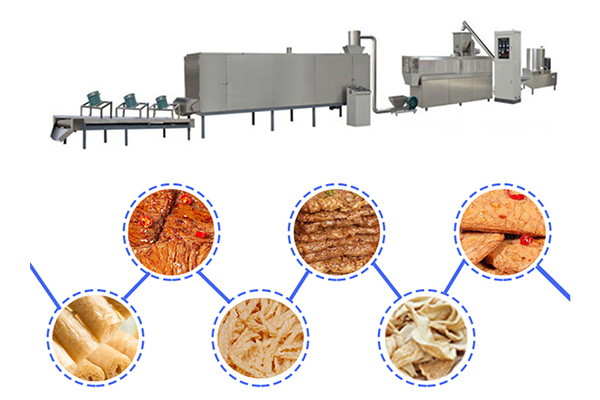

Soya Protein Making Machine

04/06/2022

Chocolate energy bar making machine

04/06/2022Macaroni Pasta Extruding Line

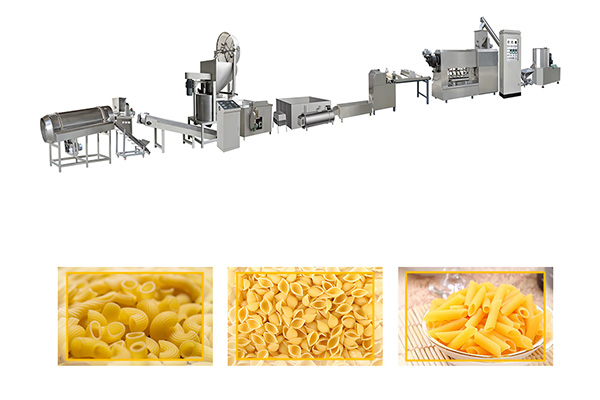

The macaroni pasta extruding line uses potato starch, corn starch, wheat flour and cassava starch,etc.. After extrusion and curing, the products can be squeezed out from the mold and cut off to produce penne rigate, fussili, shell macaroni, elbow macaroni and pasta by different moulds.

Parameters:

Model | Power(kw) | Capacity(kg/h) | Dimension(m) |

SY-100T | 81 | 100-150 | 18 x 5 x 3 |

SY-150T | 95 | 300-350 | 20 x 5 x 3 |

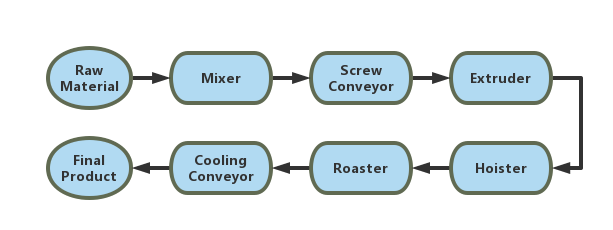

Production Flow Chart:

Mixer: Mix raw materials, water and other materials

Screw Conveyor: It is used to lift the mixed materials into the extruder hopper.

Extruder: The raw materials are evenly fed and extruded by the screws, and then sent out through the mold.

Hoister: Used to lift food into the oven

Roaster: It is used to dry the semi-finished products produced. Belt drying device is adopted, and a certain number of heating devices are installed in the oven, which are heated by electricity (steam, gas, fuel oil, etc.).

Cooling Conveyor: Used to cooling products.

Product Sample:

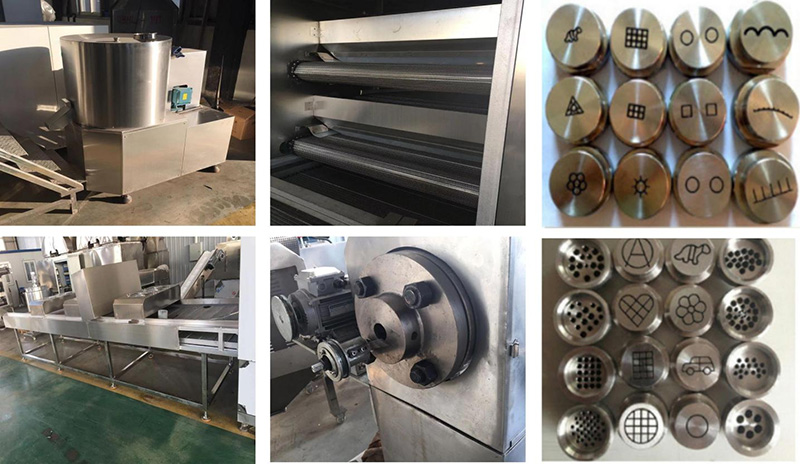

Details: