What are the parts of a dog bite production line?

Fish Food Machine Production Line

08/09/2022

Prospects for the future development of puffed food

08/15/2022Recently, many customers have asked me what they need to prepare when they want to start a new plant to produce pet bite food. Here is a unified answer to this question for you.

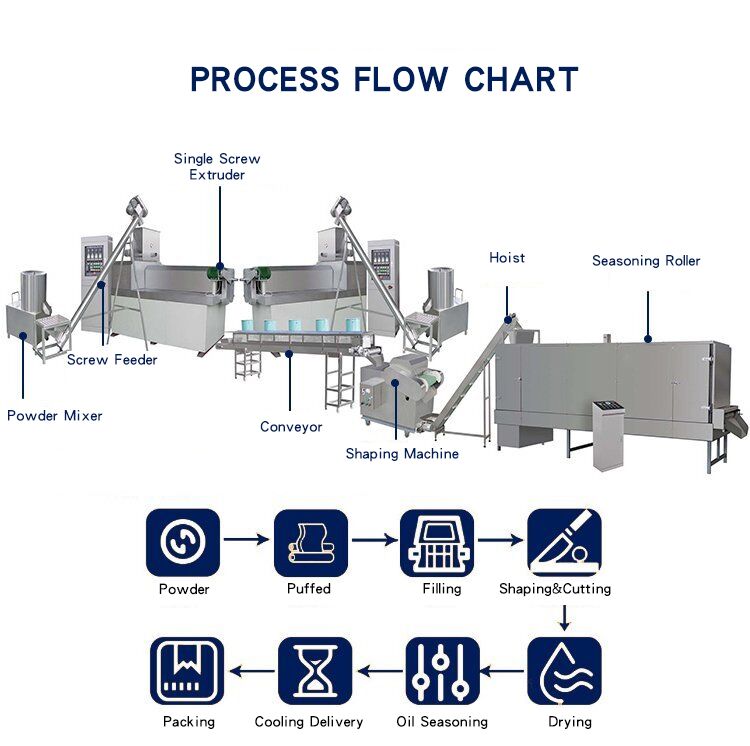

First, you need to determine the products you want to do, such as bite products, by our professional customer service, to choose the most suitable equipment for you. Including but not limited to the following equipment.

1, Mixer: add a certain percentage of water to the raw materials to mix well.

2, Loading Machine: the use of motor-powered screw conveyor, the mix of raw materials to the feed hopper of the extruder to ensure easy and fast feeding.

3, Single-Screw Extruder: in the high-temperature and high-pressure environment, the extrusion of the screw, by adjusting the process production department different feed, the specific size and shape of the particles can be replaced mold.

4, Cooling Conveyor: traction cooling conveyor.

5, Cutting Machine:cut the bite into different sizes according to the requirements.

6, Conveyor: convey the bites to the oven,

7, Multi-Layer Oven: the oven is mostly electric oven, the temperature is adjusted between 0-200 degrees by the control cabinet, the internal stainless steel double-layer mesh bag, reduce the moisture of feed particles, promote the maturation rate, increase the shelf life.

8, Packaging Machine: manual sealing machine and automatic packaging machine can be used.

Next, determine what equipment is needed, our customer service will provide you with accurate drawings that will show the footprint of the equipment, as well as set aside space for storing raw materials, how the finished product is placed. It is only necessary to find the plant that can meet these conditions.

Finally, if you want to try new products, new recipes, we can also help you experiment.