Quick knowledge on pet food production line

Quick knowledge on pet food production line

02/08/2022

Automatic vertical packaging machine in the USA

02/08/2022

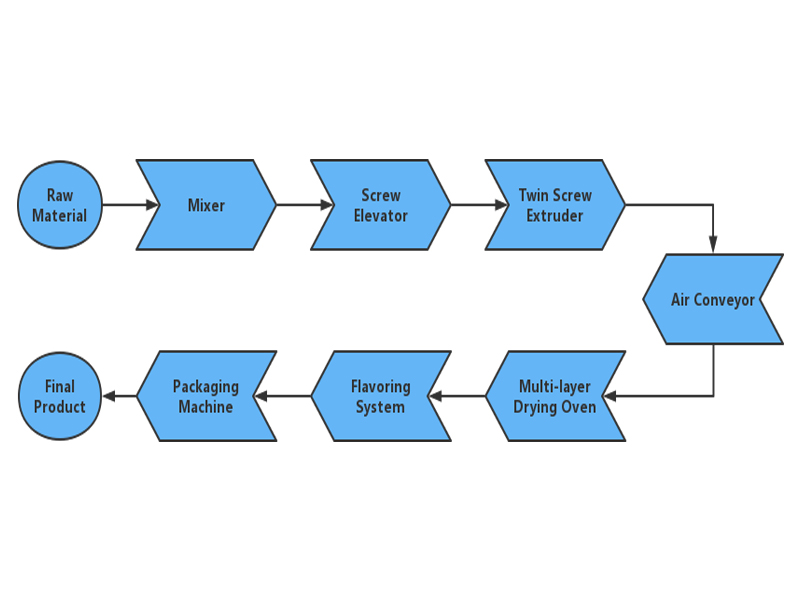

Flow Chart:

Mixer: To mix the raw materials evenly, such as corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour and additives,etc..

Screw elevator: Screw elevator is to convey the mixed materials to the feeding hopper of the extruder. This equipment is to achieve continuous and automatic working, which largely saves labor cost and increases working efficiency.

Twin screw extruder: Under the condition of high temperature, high pressure and high shear, the structure of the mixed raw materials changes and is extruded through molds of different shapes and sizes. The feed extruder adopts advanced frequency conversion speed regulation technology, which is more energy-saving and more accurate speed control. The current and speed of the motor can be directly seen through the frequency converter panel, which is simple and clear.

Air conveyor: It’s used to transport the extruded items to the multi-layer drying oven.

Multi-layer drying oven: For drying oven, we have electric one and gas oven for option. The baking temperature and speed can be controlled through the PLC. The mesh belt of oven is made of stainless steel with stable transportation and low failure rate.

Flavoring system: The fuel injector sprays oil,powder,food attractant, etc;The flavoring drum will spray oil, flavoring power, food attractant, etc. onto the pet food evenly. And the spraying quantity is controllable.

Packaging machine: Multi-head vertical packaging machine can achieve the automatic packaging from weighing to packing.